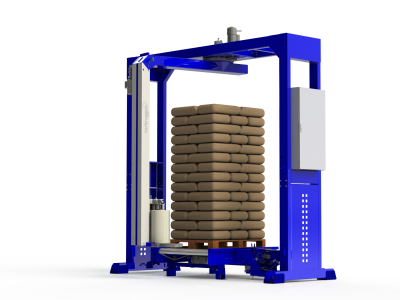

Understanding the Secret Benefits of Routine Maintenance for Your Pallet wrapping Machine

Routine maintenance of pallet wrapping equipments is essential for peak performance. It assures efficiency and reduces the possibilities of unanticipated downtime. Routine checks additionally add to a much safer working atmosphere for drivers. Furthermore, regular maintenance can result in significant price savings gradually. Understanding these benefits can transform how businesses approach devices care. What particular practices can maximize these benefits?

Boosted Machine Performance and Performance

When regular maintenance is focused on, the efficiency and performance of a pallet wrapping equipment substantially improve. Consistent maintenance guarantees that all elements operate at their finest, minimizing the chance of friction and wear that can lead to inefficiencies. Frequently inspecting and adjusting setups, such as tension and speed, allows the equipment to operate at its height, adding to smoother wrapping processes. In addition, keeping the top quality of the films utilized and keeping the maker clean stops unnecessary stress, enabling it to cover pallets much faster and with higher consistency. This boosted performance not only increases productivity but also assures that materials are made use of efficiently, eventually resulting in lower functional costs and better outcome quality. Normal upkeep consequently plays a crucial duty in optimizing the device's capacity.

Reduced Threat of Unanticipated Malfunctions

Extended Tools Lifespan

Long life is an essential benefit of maintaining pallet wrapping devices, as regular maintenance directly adds to an extended tools life-span. Normal maintenance regimens, consisting of inspections, lubrication, and components replacement, guarantee that devices run effectively and effectively. By dealing with deterioration before it rises into larger concerns, drivers can markedly reduce the chance of major fixings that might lead to expensive downtime. Furthermore, well-kept equipments are less susceptible to breakdowns, permitting smoother operations and long life in solution. This aggressive approach not just preserves the devices's performance however additionally boosts its efficiency in time. Ultimately, purchasing regular maintenance translates to a more reputable pallet wrapping device, expanding its helpful life and giving much better return on financial investment for companies.

Enhanced Safety for Operators

Preserving pallet wrapping makers not just expands their life expectancy yet additionally greatly improves safety for operators. Routine maintenance guarantees that all elements function smoothly, lowering the threat of breakdowns that can lead to accidents. By examining belts, equipments, and safety and security functions, operators can avoid prospective risks triggered by damaged or worn components. In addition, a well-kept equipment reduces the possibility of abrupt stops or jerky activities, which can create injuries throughout operation. When safety see page guards and emergency shut-off systems Resources are routinely inspected and serviced, Operators are better shielded. Ultimately, focusing on maintenance contributes to a safer working atmosphere, allowing operators to perform their tasks with confidence and substantially decreasing the threat of workplace mishaps associated with devices failure.

Price Savings With Preventative Maintenance

While unforeseen break downs can result in significant expenses, carrying out a schedule for preventative upkeep can significantly reduce general expenses connected with pallet wrapping makers. Routine assessments and prompt repair work help identify potential problems before they intensify, lessening downtime and expensive emergency fixes. By attending to deterioration proactively, organizations can expand the life expectancy of their tools, postponing the demand for expensive replacements. In addition, properly maintained equipments operate much more effectively, which can lead to lower power consumption and minimized material waste. These cost savings build up gradually, making preventative maintenance an economically sound technique (pallet wrapping machine repair). Inevitably, investing in regular maintenance not just safeguards functional effectiveness yet also adds to a much healthier profits, profiting business in the long run

Regularly Asked Concerns

Exactly how Often Should I Set Up Maintenance for My Pallet wrapping Device?

The regularity of upkeep for a pallet wrapping machine normally relies on use intensity. Routine checks every 3 to 6 months are recommended to guarantee peak performance, lengthening the maker's lifespan and minimizing unanticipated break downs.

What Details Parts Require Routine Inspection During Maintenance?

During upkeep, particular elements requiring regular examination consist of the wrapping film dispenser, stress control Your Domain Name drive, electric motor and system parts, electrical links, and security attributes. Guaranteeing these parts are working at their finest prevents breakdowns and boosts total device efficiency.

Can I Carry Out Upkeep Myself or Should I Hire a Service technician?

The choice to perform maintenance personally or employ a specialist depends on one's technological ability and comfort degree. While some may manage fundamental tasks, complex problems generally need professional proficiency for suitable safety and security and effectiveness.

What Signs Show That My Pallet wrapping Device Requirements Upkeep?

Indications indicating a demand for maintenance include uncommon noises, irregular wrapping tension, frequent mistakes, visible endure components, and reduced functional rate. Resolving these signs promptly can prevent more damages and guarantee optimal efficiency.

Where Can I Locate Replacement Parts for My Pallet wrapping Device?

To find replacement components for a pallet wrapping equipment, one can check out producer web sites, specialized industrial supply stores, or on the internet marketplaces (pallet wrapping machine repair). In addition, getting in touch with the producer's customer support may offer certain guidance on part accessibility and sourcing